August 29, 2016

Equipment could be your top snow and ice salesperson

BY MARK BRADLEY

Your equipment has a significant influence on your snow and ice sales. From the types of work, to the number of sites you can complete in a shift, right through to what you are charging, equipment plays a strong hand in the work you win each winter.

You could argue that your equipment is just as effective as a great salesperson. How? Let’s take a look at a couple of examples. Let’s say two snow and ice companies are bidding on the same property: 2.25 acres of accessible asphalt. Its difficulty is average, with no particular tight spots or challenges. For the purposes of a simple example, we are not including salting — just the plowing.

Equipment affects competitive pricing

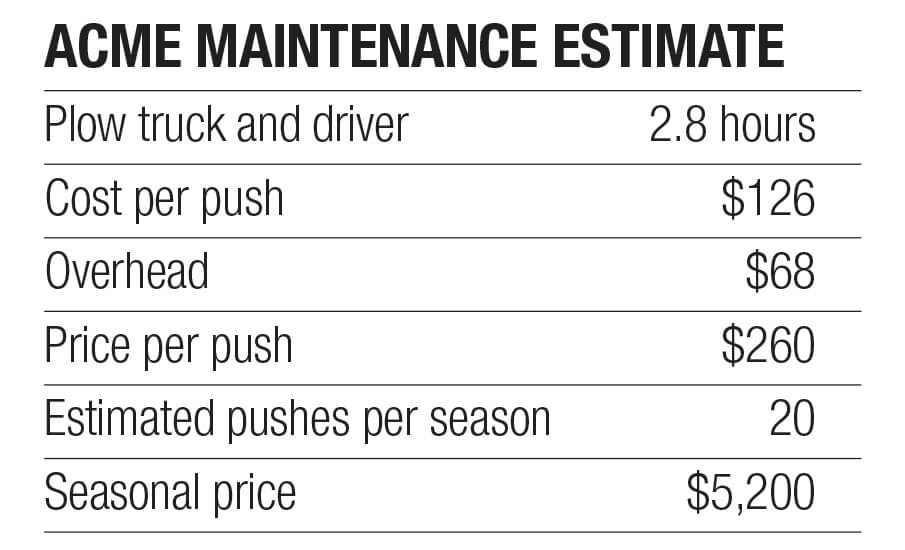

Acme Maintenance does mostly maintenance work. They don’t own any large equipment, but they do have a fleet of trucks and plows. Using a plow truck with an eight-ft. blade, Acme comes up with an estimated time of 2.8 hours to plow the lot in an average event. Their estimate, super-simplified for this example, looks something like the following:

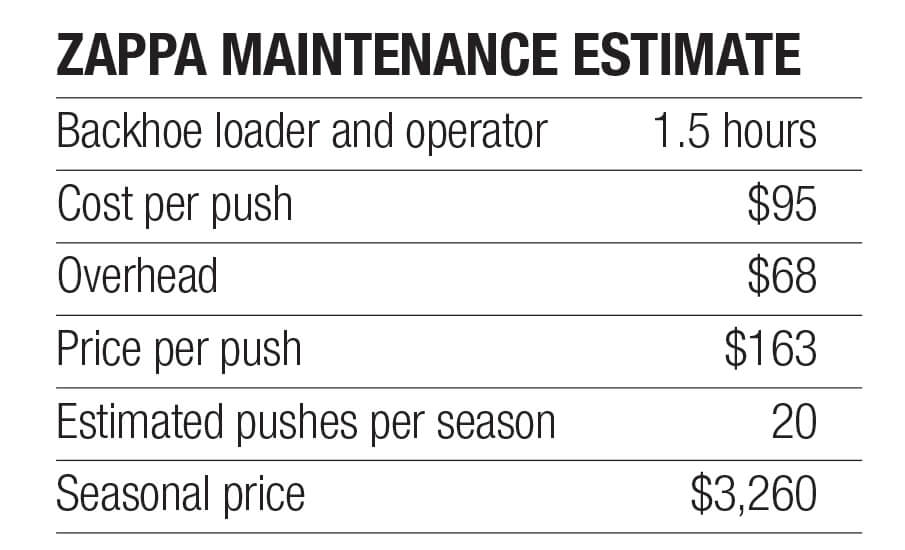

Zappa Landscaping is also bidding on this same lot. They own some backhoe loaders; using their backhoe with a 14-ft. blade, they get better productivity, but are also spending more on both equipment and operator. So, their equipment and labour costs are higher, but so too is their productivity. Using the exact same overhead and net profit margin as Acme, Zappa Landscaping’s bid is much lower as a result of the improved productivity.

Even if Zappa recovered more overhead and/or profit on their bid (if their costs are higher, they would likely recover more overhead), they still have thousands of dollars of wiggle room before they are competing with Acme’s price.

There is almost no scenario that Acme could compete and win this job, when bidding against Zappa. And Zappa is not giving work away for free either — they just found the most productive equipment for the job.

Now you might argue that Acme has the trucks — so if the job required salting, they might have the upper hand. Maybe. Let’s look at how equipment can affect salting operations in our next example.

More billable time

We all want to control costs, but we should be more concerned with cost optimization instead of cost savings. What does that mean? Think about it this way — the post office could save costs if it got rid of all mail sorting equipment. But if they got rid of that equipment, they would spend ten times (or more!) in labour, doing all that sorting far less efficiently.

Cost optimization works the same way in our landscape and snow businesses. If you are trying to avoid equipment because it increases your monthly payments, or the equipment is an expensive payment, be sure to look at cost optimization before you make any final decisions.

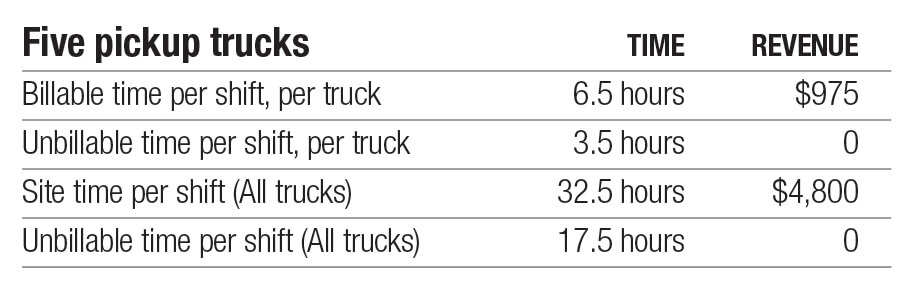

Use Acme Maintenance again as an example. Imagine they have five ¾-ton pickup trucks with plows and salters on the road during each event. Each driver starts at the yard and loads with salt. They plow and salt, but during the night they return to the salt yard to wait, then load, then sign paperwork, then return to their route. They plow and salt a few more sites, then return at the end of their shift to clean up.

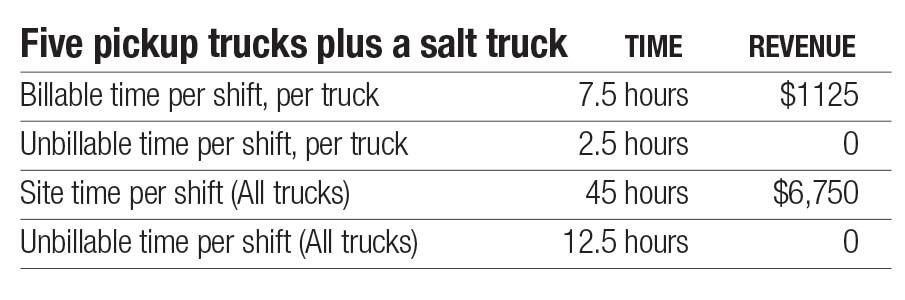

Acme could complete its routes more efficiently with a larger salt truck. Instead of all the pickup trucks salting, the larger truck is a dedicated salter. This could save money several ways:

- Acme could eliminate or reduce the size of salters on its pickups

- The pickup trucks would suffer less salt damage, requiring less time for washing and maintenance.

- Acme’s drivers would spend a lot less time loading salt and driving to and from salt yards, and could spend more time plowing. With only one dedicated salter truck having to load salt, far less often, more employees are on billable time instead of unbillable time.

- The pickup trucks could add one or more extra sites to each route, using time saved by not salting and loading salt

- during every event.

- Acme could use the larger truck in the summer, especially when equipped with a hook-lift, for large material moving, equipment mobilization, bin or disposal moving and more.

In just two events per month, Acme more than covers the cost of the salter truck lease with the extra billable time, generating more revenue per event. In this example, and factoring all the other benefits above, it looks like a good business decision.

So as the snow season approaches, take the opportunity to study the equipment you have in your fleet. Where possible, optimize your spending instead of just controlling it for the greatest impact on your bottom line.

Mark Bradley is president of TBG Landscape and LMN, based in Ontario. As always, the numbers in this article are intended to project realistic examples, but not as actual costs or savings for any specific company. Be sure to run scenarios with your own costs, revenues and time-saved estimates.